Our Journey from Passion to Precision.

Our mission is to deliver the highest quality services and products, combining innovation, precision, and flexibility. We value professionalism, integrity, and customer focus, enabling us to execute even the most demanding projects.

2001-2016

In 2001, Blender began its production operations, evolving from a small facility focused on manufacturing decorative items such as candlesticks and metal glass fittings. Established in 1999 as a trading company, the firm gained valuable experience and established relationships with international clients through trade fairs like Ambiente in Frankfurt. During this period, we focused on developing key production processes, including powder coating, welding, and sheet metal bending on our initial press brakes. By investing in our machine park, we gradually scaled up our production capabilities and improved quality, enabling us to undertake increasingly complex projects for our clients. This period was marked by intense learning, process optimization, and laying the groundwork for the company’s future growth.

Founded in 1999, we have grown from a small trading company into a modern manufacturing business. Our journey reflects passion, innovation, and technical expertise.

2016-2021

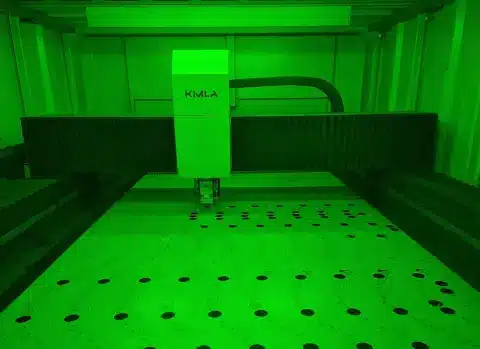

Between 2016 and 2021, we invested in the modernization of our facility, implementing new technologies and streamlining production processes. With the support of EU funds, we acquired advanced laser cutting machines, CNC metal spinners, and many other pieces of equipment that significantly enhanced our production capabilities. We also launched a fully automated powder coating line, improving the quality of our surface finishes. The expansion of our press brake fleet and the addition of new welding stations allowed us to undertake more complex projects for our clients. This was a period of intense development, where our investments in new technologies resulted in increased efficiency and production flexibility.

Our team consists of skilled engineers, technologists, and specialists who combine years of experience with the latest technological knowledge. This ensures professionalism at every stage of project execution—from design through prototyping to mass production.

2021-2023

In 2021, we began building a new, state-of-the-art manufacturing facility equipped with the latest technologies, enhancing our production flexibility and efficiency. During this period, we implemented our most advanced powder coating line, launched in early 2023, which enables faster, more efficient, and sustainable painting processes. We also installed a high-power laser with a module for cutting tubes and profiles, significantly expanding our metal processing capabilities. We introduced CNC metal spinners capable of processing discs up to 1500 mm in diameter and the latest laser welders, which provide the highest precision and quality. To further improve customer service, we built a warehouse with a capacity of 1300 pallets, serving as a backup facility, and acquired our own trucks to optimize logistics and increase delivery flexibility. These investments allow us to effectively support demanding industries such as lighting, yacht production, caravaning, automotive, machinery, and enclosure manufacturing.

We invest in the latest technologies to meet the growing demands of the market. Our modern machinery, automated processes, and innovative approach enable us to undertake complex technical projects, enhancing efficiency and precision in production.

Our quality is backed by numerous certifications, including ISO 9001 and FSC, along with the prestigious German Design Award. These accolades highlight our commitment to innovation, attention to detail, and the highest standards in our products.

We provide solutions for various industries, executing projects from concept to final product. Our case studies demonstrate how we effectively support our clients, delivering products and components that meet their expectations and technical requirements